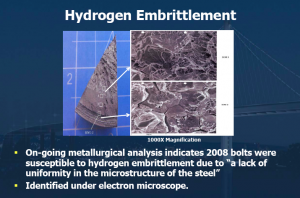

The Metropolitan Transportation Commission (MTC) and Caltrans say they will replace or reinforce all 96 of the 2008 anchor bolts installed in the new eastern span of the Bay Bridge, not just the 30 that have failed so far. Those bolts snapped within days of being tightened this March.

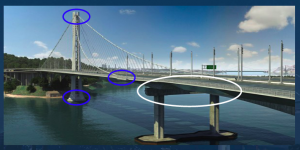

MTC Executive Director Steve Heminger also today unveiled two possible design solutions, down from three, to ensure the seismic safety of the bridge. But Heminger told members of the Bay Area Toll Authority that he couldn't give a timeline for a repair for another two weeks.

There are plenty of other open questions, too.

One of those is what to do with 192 similar bolts installed on the bridge. This batch was manufactured in 2010 to the same specifications as the ones that gave way. So far none of the 2010 bolts have shown weakness and initial testing seems to suggest they are stronger.