At first glance, the metallic device almost looks like a high-tech bike pedal. Or maybe the latest cooking gadget for zesting lemons. Or, perhaps, it's a secret weapon for X-Men superhero Wolverine.

But look again.

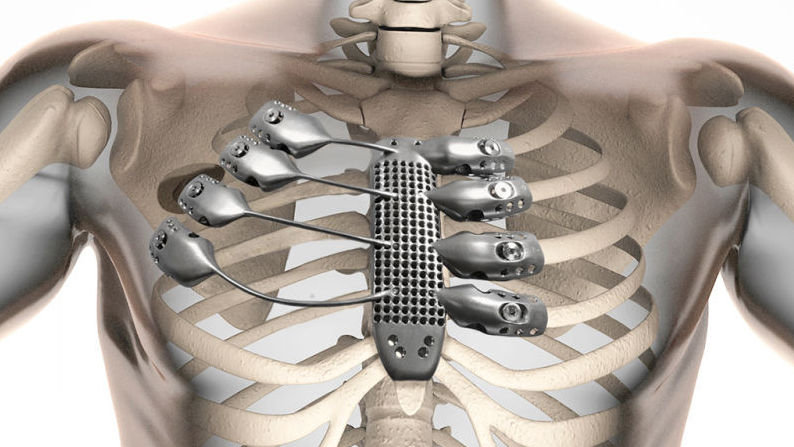

Doctors in Spain say this is the world's first 3-D-printed rib cage, made entirely from titanium. And they've already implanted the device into the chest of a 54-year-old cancer patient. The man lost his sternum and pieces of four ribs when doctors removed a large tumor.

The perforated center section of the implant is the prosthetic sternum. Four thin rods on the left mimic ribs. They're thin and flexible so they can bend during breathing. The eight clamps on either side attach the implant to bone. Screws hold the clamps in place.

Surgeons at Salamanca University Hospital reported the man's case — and how they made the prosthesis — last month in the European Journal of Cardio-Thoracic Surgery.

9(MDAxOTAwOTE4MDEyMTkxMDAzNjczZDljZA004))